Design and Manufacture of Textile Composites: Woodhead Publishing in Textiles

Textiles are a versatile material with a wide range of applications, from clothing to medical devices. In recent years, there has been growing interest in the use of textiles in composite materials. Textile composites are made by combining textiles with other materials, such as polymers, metals, or ceramics, to create a material with improved properties.

Textile composites offer a number of advantages over traditional composite materials. They are lightweight, flexible, and strong. They are also resistant to heat and chemicals. Textile composites can be used in a variety of applications, including aerospace, automotive, and medical devices.

4.4 out of 5

| Language | : | English |

| File size | : | 32721 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 492 pages |

The design and manufacture of textile composites is a complex process. It requires a deep understanding of both textile and composite materials. The following is a brief overview of the design and manufacture of textile composites:

Design

The first step in the design of a textile composite is to select the appropriate materials. The choice of materials will depend on the desired properties of the composite. For example, if the composite needs to be lightweight and flexible, then a textile made from a lightweight fiber, such as carbon fiber, would be a good choice. If the composite needs to be strong and resistant to heat, then a textile made from a high-temperature fiber, such as ceramic fiber, would be a good choice.

Once the materials have been selected, the next step is to design the composite structure. The structure of the composite will depend on the desired properties of the composite. For example, if the composite needs to be strong in tension, then it would be designed with a high fiber content in the direction of the load. If the composite needs to be resistant to impact, then it would be designed with a high fiber content in the direction of the impact.

Manufacture

The manufacture of textile composites is a complex process that requires specialized equipment and expertise. The following is a brief overview of the manufacturing process:

- Preforming: The first step in the manufacturing process is to create a preform. The preform is a three-dimensional shape that is made from the textile materials. The preform is typically created by weaving, knitting, or braiding the textile materials together.

- Molding: The preform is then placed in a mold. The mold is a cavity that is shaped to the desired shape of the composite. The mold is then closed and the preform is impregnated with a resin. The resin is a liquid that hardens into a solid when it is cured.

- Curing: The mold is then heated to cure the resin. The curing process can take several hours or even days. Once the resin is cured, the composite is removed from the mold.

- Finishing: The composite is then finished to give it the desired surface finish. The finishing process may include sanding, painting, or coating the composite.

Applications

Textile composites are used in a wide range of applications, including:

- Aerospace: Textile composites are used in a variety of aerospace applications, such as aircraft wings, fuselage, and control surfaces. Textile composites are lightweight and strong, which makes them ideal for use in aerospace applications.

- Automotive: Textile composites are used in a variety of automotive applications, such as body panels, bumpers, and interior trim. Textile composites are lightweight and durable, which makes them ideal for use in automotive applications.

- Medical devices: Textile composites are used in a variety of medical devices, such as artificial joints, surgical implants, and wound dressings. Textile composites are biocompatible and resistant to wear and tear, which makes them ideal for use in medical devices.

Future

The future of textile composites is bright. As the demand for lightweight, strong, and durable materials continues to grow, the use of textile composites is expected to increase. Textile composites are a versatile material with a wide range of applications. They are lightweight, flexible, strong, and resistant to heat and chemicals. Textile composites are used in a variety of applications, including aerospace, automotive, and medical devices. The future of textile composites is bright.

References

- Hearle, J. W. S., & Hollick, L. (2004). Handbook of textile fibres. CRC Press.

- Hull, D., & Clyne, T. W. (1996). An to composite materials. Cambridge University Press.

- Mallick, P. K. (2008). Fiber-reinforced composites: materials, manufacturing, and design. CRC Press.

4.4 out of 5

| Language | : | English |

| File size | : | 32721 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 492 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Top Book

Top Book Novel

Novel Fiction

Fiction Nonfiction

Nonfiction Literature

Literature Paperback

Paperback Hardcover

Hardcover E-book

E-book Audiobook

Audiobook Bestseller

Bestseller Classic

Classic Mystery

Mystery Thriller

Thriller Romance

Romance Fantasy

Fantasy Science Fiction

Science Fiction Biography

Biography Memoir

Memoir Autobiography

Autobiography Poetry

Poetry Drama

Drama Historical Fiction

Historical Fiction Self-help

Self-help Young Adult

Young Adult Childrens Books

Childrens Books Graphic Novel

Graphic Novel Anthology

Anthology Series

Series Encyclopedia

Encyclopedia Reference

Reference Guidebook

Guidebook Textbook

Textbook Workbook

Workbook Journal

Journal Diary

Diary Manuscript

Manuscript Folio

Folio Pulp Fiction

Pulp Fiction Short Stories

Short Stories Fairy Tales

Fairy Tales Fables

Fables Mythology

Mythology Philosophy

Philosophy Religion

Religion Spirituality

Spirituality Essays

Essays Critique

Critique Commentary

Commentary Glossary

Glossary Bibliography

Bibliography Index

Index Table of Contents

Table of Contents Preface

Preface Introduction

Introduction Foreword

Foreword Afterword

Afterword Appendices

Appendices Annotations

Annotations Footnotes

Footnotes Epilogue

Epilogue Prologue

Prologue William O Daly

William O Daly Nnedi Okorafor

Nnedi Okorafor Dandi Palmer

Dandi Palmer Zach Abraham

Zach Abraham Elizabeth Briggs

Elizabeth Briggs Couriosity Inc

Couriosity Inc Taylor Adams

Taylor Adams Marc Collins

Marc Collins Naomi Alderman

Naomi Alderman Greg Puciato

Greg Puciato Jean Marie Bauhaus

Jean Marie Bauhaus S Rae

S Rae John Kennedy Toole

John Kennedy Toole Martin Cate

Martin Cate Mike Marvin

Mike Marvin Douglas Doman

Douglas Doman Lay Flat Paperback Edition Kindle Edition

Lay Flat Paperback Edition Kindle Edition Dr Sushma Gupta

Dr Sushma Gupta Jim Fay

Jim Fay Jeff Brooker

Jeff Brooker

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Mikhail BulgakovWarrior Instinct Cerberus Tactical K9 Team Bravo: A Force to be Reckoned With

Mikhail BulgakovWarrior Instinct Cerberus Tactical K9 Team Bravo: A Force to be Reckoned With

Robert Louis StevensonAn Anthology Dedicated to the Voices of Queer Poets of Color: A Journey into...

Robert Louis StevensonAn Anthology Dedicated to the Voices of Queer Poets of Color: A Journey into...

Samuel WardThe Essential Guide to Diet, Medicine, and Well-being: A Helping Hand for a...

Samuel WardThe Essential Guide to Diet, Medicine, and Well-being: A Helping Hand for a... Vladimir NabokovFollow ·5.2k

Vladimir NabokovFollow ·5.2k Dion ReedFollow ·19.8k

Dion ReedFollow ·19.8k Jerry WardFollow ·14.9k

Jerry WardFollow ·14.9k Enrique BlairFollow ·18.4k

Enrique BlairFollow ·18.4k Dale MitchellFollow ·7.6k

Dale MitchellFollow ·7.6k Ricky BellFollow ·18k

Ricky BellFollow ·18k Sammy PowellFollow ·4.6k

Sammy PowellFollow ·4.6k Sam CarterFollow ·16.8k

Sam CarterFollow ·16.8k

David Peterson

David PetersonUnveiling Eleven of the Wheel of Time: A Journey Through...

In the vast and intricate...

Curtis Stewart

Curtis StewartEbony Jay Rice: A Rising Star in the Entertainment...

Ebony Jay Rice is a force to be reckoned...

Matt Reed

Matt ReedNavigating Mental Health with Science: Overcoming...

Mental health is an integral part of...

Guillermo Blair

Guillermo BlairFormer Magistrate's Poetic Reflections on Love and...

In the hallowed halls...

Corey Green

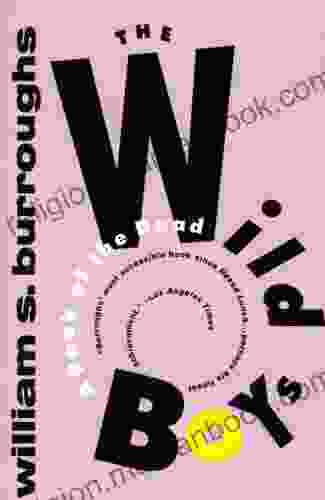

Corey GreenOf the Dead: William Burroughs' Post-Beat Masterpiece

William S. Burroughs' Of the...

4.4 out of 5

| Language | : | English |

| File size | : | 32721 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 492 pages |